Automation in construction is no longer just a futuristic buzzword. It’s here, it’s real, and it’s changing how we build. From self-driving excavators to AI-powered scheduling tools, the construction industry is rapidly integrating automation. Yet, while some tasks benefit immensely, others hit walls due to complexity, cost, or human nuance.

In this blog, we’ll break down exactly where automation in construction works, where it doesn’t, and what business leaders should prioritize. Whether you’re a project manager, operations head, or construction tech innovator, this guide gives you clarity.

Why Automation in Construction Matters to Your Business

In an industry battling labor shortages, rising material costs, and increasing safety risks, automation offers a much-needed edge.

Why should companies care? Because automation isn’t just about robots and AI — it’s about doing more with less, reducing human error, and speeding up delivery.

Who benefits most?

- Contractors managing complex, multi-phase projects

- Developers racing against tight deadlines

- Site supervisors juggling labor and logistics daily

Real-world use cases:

- Drones can conduct daily site inspections in 30 minutes instead of 3 hours.

- Automated rebar tying machines cut labor time by up to 40%.

- AI scheduling software reduces delays by predicting risks before they escalate.

Yet, not every task is ready for automation. Let’s explore what works — and what doesn’t.

Best Practices: Where Automation Works in Construction (And Where It Doesn’t)

Where Automation Works Well

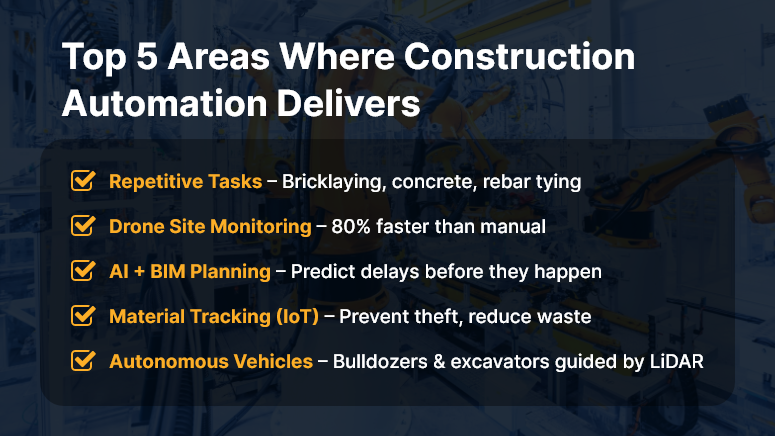

- Repetitive, Labor-Intensive Tasks

Tasks like bricklaying, concrete pouring, and rebar tying are ideal for automation. Robots excel in consistency and reduce strain injuries. - Site Monitoring with Drones

Drones can capture aerial data, track progress, and flag safety violations — faster and safer than manual inspection. - BIM and AI for Planning

Building Information Modeling (BIM) tools integrated with AI help teams forecast project timelines and detect clashes before construction begins. - Material Tracking with IoT

Sensors and RFID tags provide real-time visibility into material usage, preventing delays and theft.

- Automated Equipment and Vehicles

Self-driving bulldozers and excavators, guided by GPS and LiDAR, enhance precision and reduce accidents.

Where Automation Still Struggles

- Creative or Judgment-Based Work

Design, problem-solving, and on-the-fly decisions still require human nuance. - Unstructured Environments

Construction sites are dynamic. Not all robots or machines can adapt to terrain changes, weather, or unexpected events. - Specialized Trade Work

Tasks like plumbing, electrical wiring, or HVAC installation demand precision and adaptability — not ideal for current automation tools. - High Cost vs. ROI

Some technologies remain too expensive for mid-sized contractors with slim margins.

Quick Wins & Do’s and Don’ts

Do:

- Start small — automate one workflow (like timesheet tracking or site inspection).

- Train your workforce to work with, not against, machines.

- Choose tech that integrates with your current construction platform.

Don’t:

- Don’t automate for the sake of it. Align automation to business goals.

- Avoid tools with steep learning curves or poor support.

- Don’t ignore data security — automated systems need secure infrastructure.

Framework to Apply:

- Step 1: Identify repetitive, high-volume tasks

- Step 2: Evaluate ROI of automating each

- Step 3: Pilot-test with one team or project

- Step 4: Train users and monitor adoption

- Step 5: Expand with feedback and continuous improvement

Use Case Example

For example, Skyline Builders, a mid-sized commercial construction company, used drone-based site inspections and AI-based progress tracking on a 12-month high-rise project.

Using the automated system reduced inspection time by 80%, flagged delays early, and improved compliance reporting — all without increasing overhead.

Here’s how: The drone captured daily images. The AI analyzed patterns against the project timeline. The team received visual reports that saved hours of manual coordination.

Key Takeaways & Closing Summary

Automation in construction is a powerful enabler — but only when used strategically.

- It works best in repetitive, data-heavy, or dangerous tasks like site inspections, material tracking, and earthwork.

- It still struggles with tasks that demand creativity, adaptability, or deep trade expertise.

- Start small. Pilot-test. Train your team. Choose scalable tools.

The future of construction isn’t human vs. machine — it’s humans empowered by smart, integrated automation.