Did you know that 9 out of 10 construction projects exceed their budget? Whether it’s a residential build, commercial infrastructure, or a government contract, blowing past the planned costs has become the norm rather than the exception.

From material price fluctuations to poor planning and lack of real-time tracking, the reasons are many, but the consequences are always the same: delays, disputes, and damaged reputations.

In this blog, we’ll break down why construction projects go over budget, what mistakes to avoid, and how you can prevent cost overruns with digital project management tools like OConstruction.

Business Relevance & Why It Matters

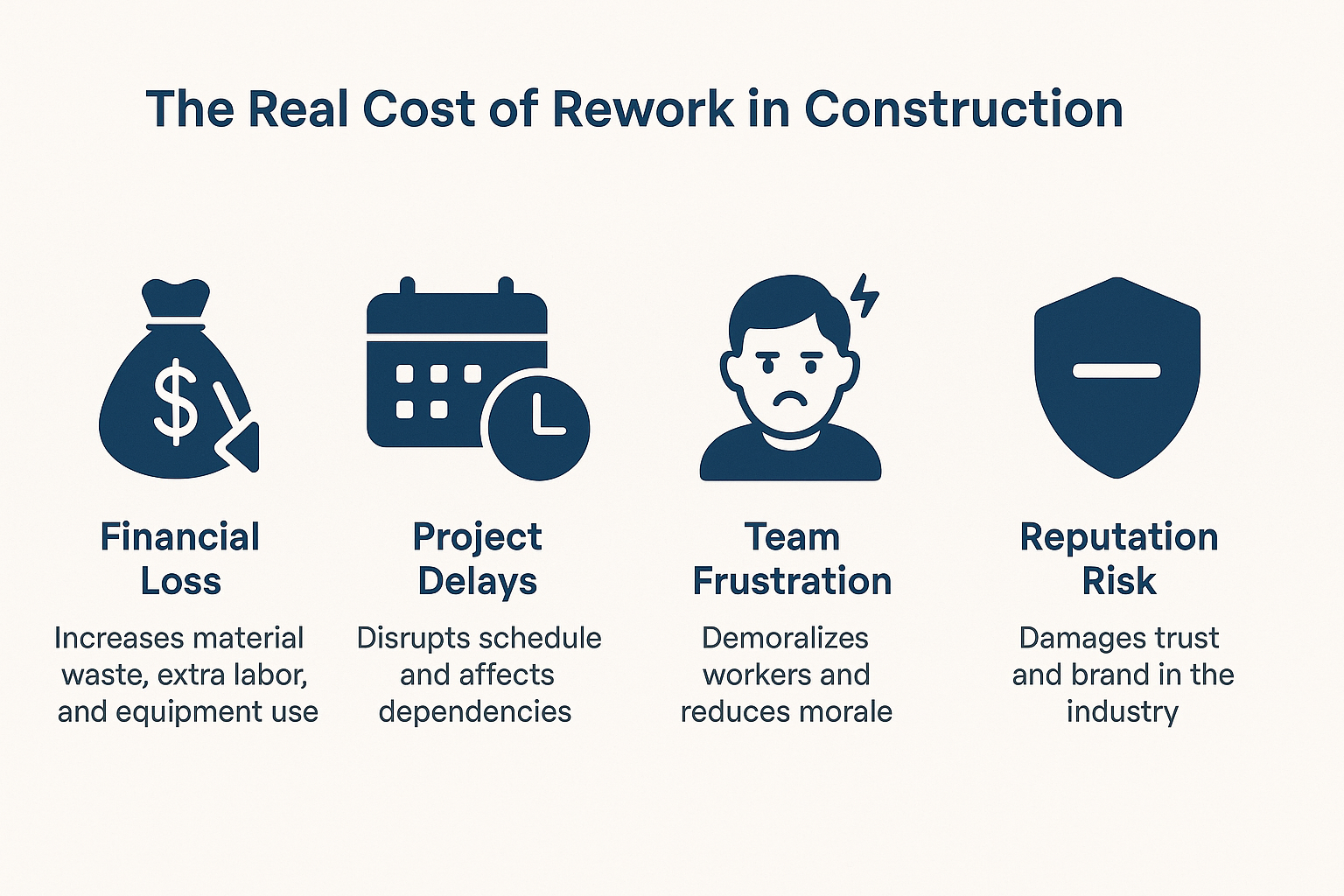

For construction businesses, accurate budgeting isn’t just a financial necessity—it’s a strategic advantage. Budget overruns lead to:

- Shrinking profit margins

- Lost client trust

- Project delays and rework

- Legal or contractual penalties

Who should care?

- Project Managers are trying to stay on schedule

- Finance & Procurement teams are monitoring costs

- Contractors bidding for new jobs

- Operations heads scaling multiple projects

Use Case 1: A mid-sized contractor wins a hospital construction tender but underestimates steel prices. Six months in, they’re 18% over budget and forced to renegotiate terms.

Use Case 2: A real estate developer launches five residential towers simultaneously but lacks real-time cost visibility. Cost overruns on two sites derail cash flow for the remaining three.

The takeaway: You can’t eliminate unpredictability in construction, but you can eliminate guesswork, miscommunication, and inefficient tracking.

Best Practices, Frameworks, and Actionable Strategies

Do’s and Don’ts of Budget Control

Do: Conduct detailed cost estimation before kickoff

Break down each project phase—design, permits, labor, materials, contingency. Don’t just lump it into one “build” line item.

Don’t: Assume past project budgets will always match future ones

Prices for materials, fuel, labor, and logistics vary. Recheck market conditions and local pricing.

Do: Set up a centralized cost-tracking system

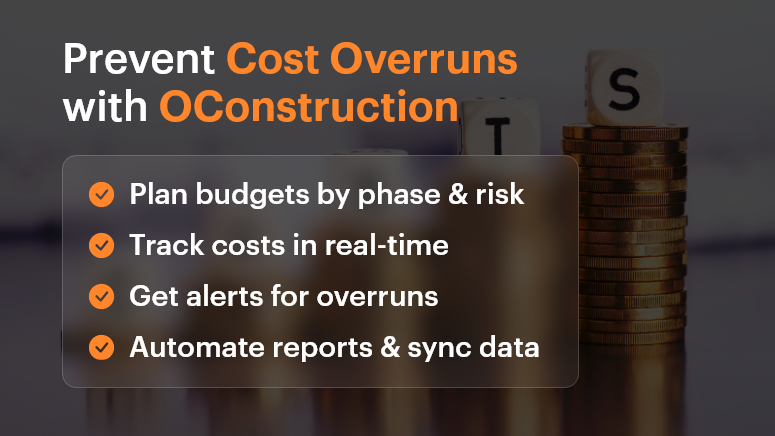

Use OConstruction’s dashboard to assign cost codes, track spending in real time, and compare actual vs. forecast.

Don’t: Rely on spreadsheets or disconnected tools

Manual tracking leads to errors, version control issues, and missed updates.

Quick Wins to Control Costs Early

- Baseline your budget early. Set realistic expectations with internal stakeholders and clients.

- Use templates and historical data. Leverage past projects in OConstruction to create smarter forecasts.

- Account for risks. Add a 5-15% contingency buffer for unknowns.

- Define a change order process. Make sure scope changes are documented, approved, and re-costed before execution.

A 5-Step Framework to Prevent Construction Cost Overruns

- Scope Planning

Define deliverables, responsibilities, and phases clearly with all stakeholders. Avoid vague assumptions.

- Detailed Estimation

Include unit costs, productivity rates, lead times, and inflation where relevant.

- Digital Budget Tracking

Use OConstruction’s project financials module to track committed costs, invoices, and payments in one place.

- Issue and Delay Management

Set up automated alerts for schedule slips, budget thresholds, or material delays.

- Regular Reporting & Forecasting

Generate weekly reports. Adjust projections as needed based on actuals.

Tip: Integrate OConstruction with your accounting or ERP tool for seamless data sync.

Customer Story

For example, Summit Build, a commercial construction firm, used OConstruction’s cost-tracking feature to cut down 12% in preventable overruns within just two quarters.

They were managing three hospital projects and used the platform to:

- Set real-time alerts when labor costs exceed benchmarks

- Automate change order documentation and approval workflows

- Visualize actual vs. forecasted spend in a single dashboard

The result? $750K saved, faster billing cycles, and improved team accountability.

Key Takeaways

Cost overruns are one of the biggest threats to profitability in construction. But they’re not inevitable.

With proper planning, real-time tracking, and digital tools like OConstruction, you can identify risks early, make smarter decisions, and keep your projects on budget and on time.

Start small, implement one strategy at a time, and scale with confidence.