The construction industry loses over $177 billion annually due to productivity inefficiencies, according to the U.S. Bureau of Labor Statistics. Delays, miscommunication, manual paperwork, and uncoordinated teams often slow down project delivery — and cost businesses big.

Improving construction site productivity isn’t just about doing things faster; it’s about doing them smarter, with fewer mistakes and more control.

This blog breaks down common productivity pitfalls, provides proven strategies to address them, and explains how platforms like OConstruction empower teams to deliver projects on time, every time.

Why Construction Site Productivity Matters More Than Ever

Construction timelines are tighter. Budgets are stricter. And labor shortages are becoming the new normal.

In this high-pressure environment, site productivity has a direct impact on profitability and reputation.

Why companies must prioritize it:

- Every delay increases overhead costs. Idle equipment, overworked labor, and stalled supply chains stack up quickly.

- Poor productivity triggers rework. Miscommunication or missing documents lead to duplicated effort — and wasted time.

- Manual tracking drains resources. Paper logs and spreadsheets slow down approvals, reporting, and decision-making.

Who benefits from better construction site productivity?

- Project Managers gain better control and insight into daily progress.

- Site Supervisors reduce chaos by streamlining task assignments and check-ins.

- Executives gain accurate forecasting, timelines, and resource usage metrics.

Real-World Pain Points:

- A crew waits for a delayed delivery because the procurement team wasn’t updated in time.

- A subcontractor misses key instructions hidden in an email chain.

- An outdated site log causes the project timeline to fall behind.

All of these are fixable — with the right processes and tech.

Best Practices to Boost Construction Site Productivity

Let’s explore practical, high-impact ways to boost productivity on the ground — backed by digital construction tools.

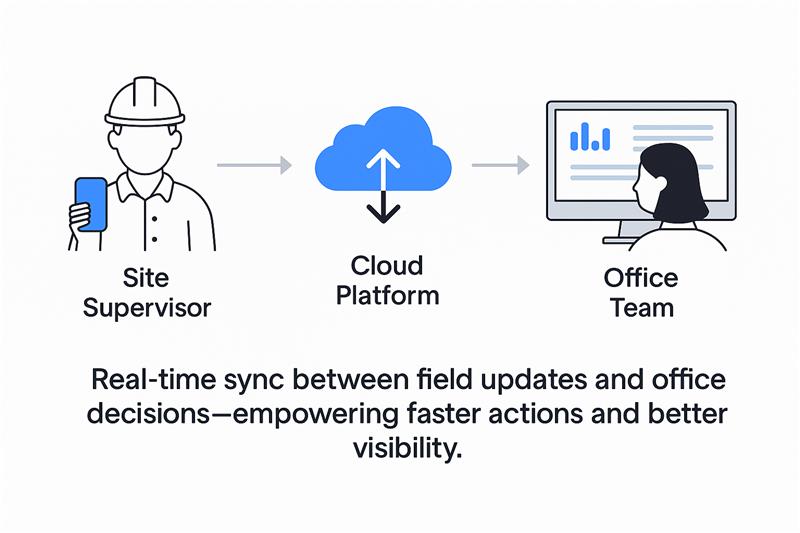

DO: Digitize Field Operations

- Replace paper-based field logs with mobile data entry that allows supervisors and workers to report in real time.

- With tools like OConstruction’s daily log feature, updates sync instantly to central dashboards — improving visibility across the team.

DON’T: Rely on Manual Scheduling

- Construction schedules change constantly. Manual updates cause delays.

- Use real-time scheduling software to shift tasks, assign resources, and notify teams without the lag.

DO: Standardize Daily Workflows

- Create repeatable, checklist-based workflows for daily tasks, inspections, and safety protocols.

- This reduces guesswork and ensures every team operates with the same playbook.

DO: Encourage Real-Time Communication

- Adopt team messaging tools that connect the office, field, and vendors in one place.

- No more back-and-forth across phone calls, WhatsApp groups, and email threads.

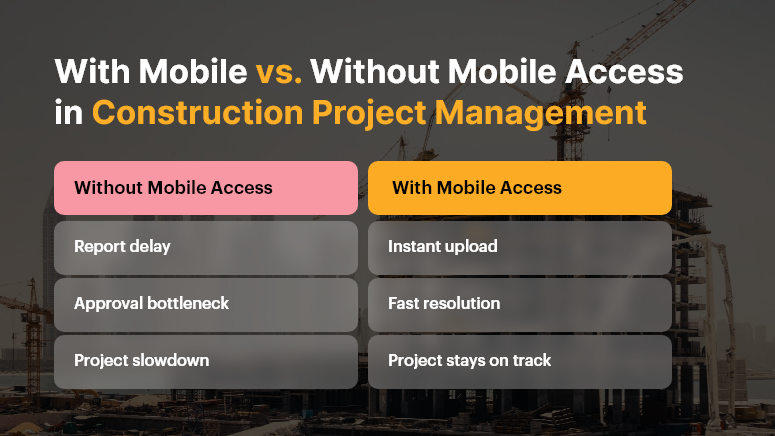

DON’T: Wait Until End-of-Day for Updates

- Status reports shouldn’t be compiled after 6 PM. That’s outdated.

- Encourage live updates from the field, integrated into your project dashboards for immediate insights.

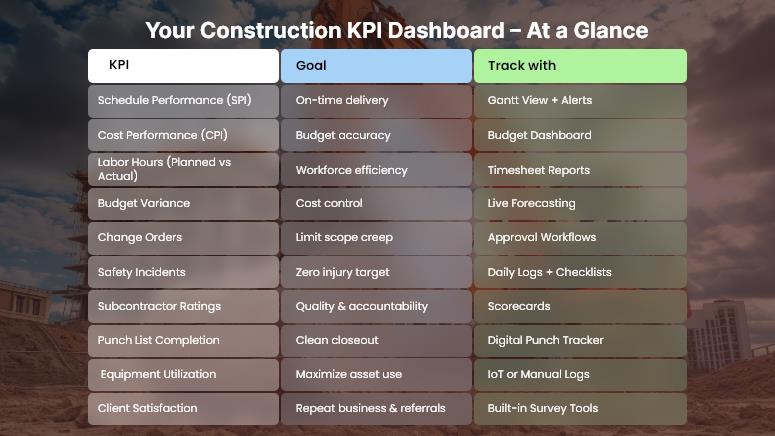

DO: Track and Analyze Productivity Metrics

Use dashboards to monitor:

- Completed tasks vs. planned tasks

- Idle time

- Workforce output

- On-time delivery rate

OConstruction lets you customize KPIs, so your productivity tracking aligns with your project goals.

Quick Wins to Apply Immediately

- Geo-tag field updates to verify locations.

- Digitally assign tasks with deadlines and automatic reminders.

- Automate safety checklists to save admin time.

Use Case: A Real Productivity Transformation

For example, Ironstone Builders, a mid-sized commercial contractor, was struggling with coordination across multiple job sites. Paper logs, missed calls, and scattered spreadsheets slowed down their daily operations.

Here’s how they improved construction site productivity using OConstruction:

- Field crews began logging hours and progressed directly from their phones.

- Project managers received real-time alerts when deliveries were late or tasks were delayed.

- Daily reports were auto-generated, reviewed by leadership every morning.

Key Takeaways & Final Thoughts

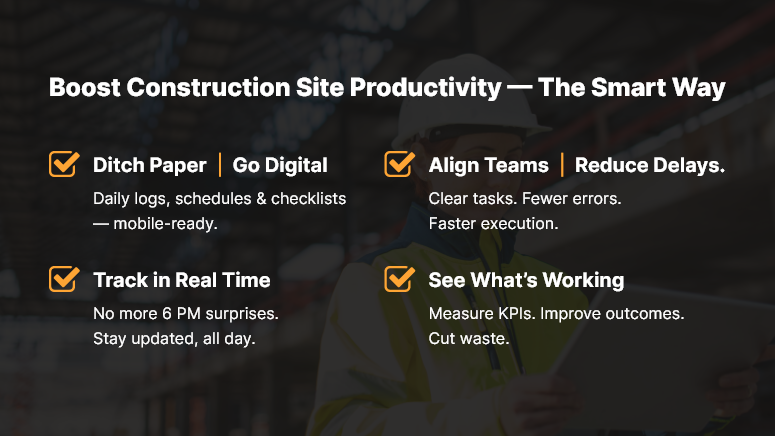

Boosting construction site productivity doesn’t require overhauling your entire operation overnight. It starts with small, strategic changes — and the right tools.

Key takeaways:

- Digitizing field updates reduces lag and improves accuracy.

- Real-time dashboards offer visibility that paper cannot.

- Standard workflows create consistency, accountability, and speed.

- Integrated platforms like OConstruction allow seamless collaboration between the field and the office.

If your teams are still juggling paperwork, chasing updates, and reacting to delays — it’s time to level up. Smart construction starts with smart systems.