Completing a construction project isn’t just about finishing the build — it’s about closing it out properly. Did you know that nearly 30% of construction projects face disputes or delays due to poor closeout processes?

Whether it’s missing documentation, incomplete inspections, or overlooked punch-list items, neglecting the project closeout phase can lead to costly delays and frustrated clients.

That’s where project closeout checklists come in. They act as your final roadmap, ensuring every critical task is completed before handing over the project.

In this blog, we’ll explore why project closeout checklists matter, the key steps involved, and how integrating OConstruction’s platform can simplify and streamline your closeout process.

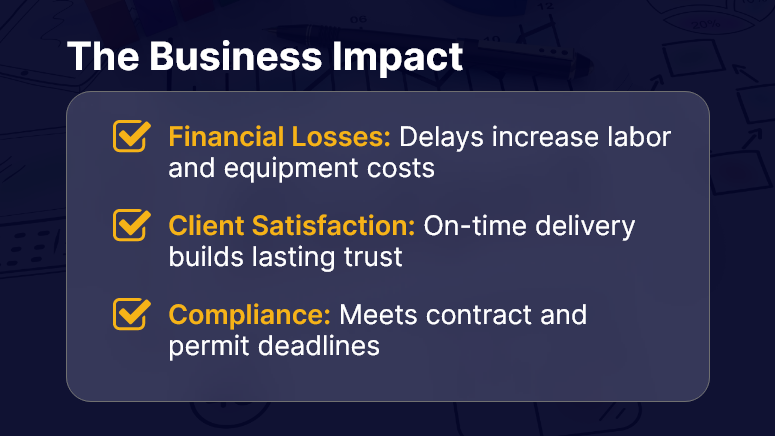

Business Relevance & Why Project Closeout Checklists Matter

The construction closeout phase often determines client satisfaction and project profitability. A detailed project closeout checklist guarantees all requirements are met — from final inspections and documentation to warranties and client training.

Why should construction companies care?

- Reduce Disputes: Clear documentation limits legal risks and misunderstandings.

- Improve Cash Flow: Efficient closeout accelerates final payments.

- Boost Client Trust: Delivering a fully complete and organized project builds your reputation.

Who benefits the most?

- Project Managers ensure nothing slips through the cracks.

- Contractors get paid faster and reduce rework.

- Clients and Developers receive smooth handovers with clear expectations.

Common challenges without checklists:

- Missed inspections cause costly rework.

- Lost warranties or manuals delay maintenance.

- Incomplete punch lists reduce client confidence.

By contrast, a well-designed checklist powered by OConstruction’s integrated tools keeps all teams aligned and accountable.

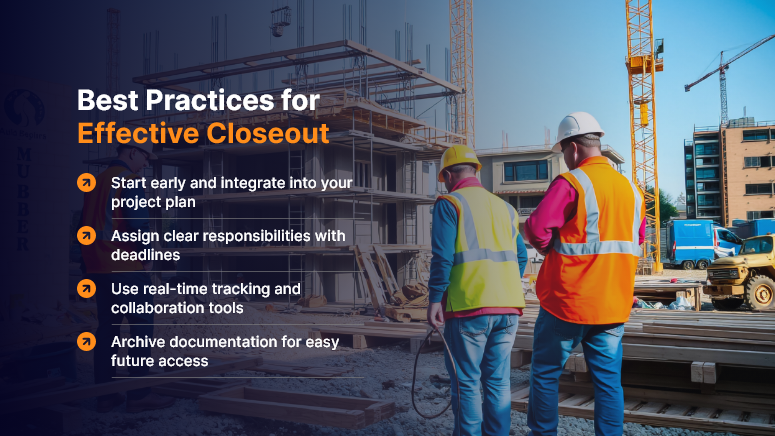

Best Practices for Project Closeout Checklists

Do’s and Don’ts

- Do start your checklist early — incorporate closeout tasks during planning and execution.

- Don’t treat the checklist as a formality; use it actively to track progress and assign responsibility.

- Do include all stakeholders — subcontractors, suppliers, and clients — in the closeout process.

- Don’t overlook documentation — warranties, permits, and manuals are essential.

Key Closeout Checklist Items

- Final Inspections: Confirm all inspections meet code and contract requirements.

- Punch List Completion: Track and resolve every outstanding issue before handover.

- Documentation Gathering: Collect all warranties, manuals, as-builts, and permits.

- Financial Closure: Verify invoices, retainage release, and final payments.

- Client Training & Handover: Provide operational training and clear communication.

Step-by-Step Framework

- Create a Customizable Checklist: Tailor it for each project’s scope and requirements using OConstruction’s digital templates.

- Assign Tasks and Deadlines: Delegate checklist items to responsible teams with automated reminders.

- Track Progress in Real-Time: Utilize OConstruction dashboards to monitor completion status and instantly flag delays.

- Collaborate Seamlessly: Enable real-time updates and communication among all stakeholders directly within the platform.

- Archive for Future Reference: Maintain a digital closeout archive for warranties and lessons learned, accessible anytime.

By embedding your project closeout checklists into OConstruction, you reduce errors, save time, and improve overall project quality.

Customer Success Story

For example, Skyline Builders, a residential construction firm, struggled with delayed handovers and frequent punch list rework. After adopting OConstruction’s checklist and collaboration features, they:

- Reduced punch list items by 40% through early tracking.

- Shortened closeout timelines by 25%.

- Increased client satisfaction scores by delivering well-documented handovers.

This streamlined closeout process not only saved money but also helped Skyline win more repeat business.

Key Takeaways & Closing Summary

In construction, the final step is just as critical as the first. Using project closeout checklists ensures no detail is missed, enabling smooth transitions from build to operation.

- Start early and customize your checklist for each project.

- Keep all stakeholders involved and accountable.

- Leverage digital tools like OConstruction for real-time tracking and collaboration.

A strong closeout process means faster payments, fewer disputes, and happier clients — making it an essential part of construction project success.

Frequently Asked Questions

1. What should a construction project closeout checklist include?

A good checklist covers final inspections, punch list completion, warranty and documentation collection, financial closure, and client training. It ensures all deliverables are verified before handover.

2. When should I start preparing for project closeout?

Closeout planning should start early — ideally during project planning. This way, you can assign responsibilities, avoid last-minute rush, and integrate closeout tasks seamlessly into the workflow.

3. How does a checklist improve client satisfaction?

A checklist ensures nothing is overlooked, from safety inspections to documentation. This builds trust with clients, speeds up handover, and reduces the chance of disputes or rework.

4. What are the risks of not using a project closeout checklist?

Without one, teams often face delays, missed inspections, incomplete documentation, lost warranties, and disputes over unfinished work. This can hurt cash flow and damage client relationships.

5. How can digital tools like OConstruction improve closeout checklists?

Platforms like OConstruction allow you to create customizable checklists, assign responsibilities, track tasks in real time, collaborate across teams, and archive documents — making the entire closeout process faster, error-free, and transparent.