Digital transformation in construction used to be a competitive edge — now it’s survival.

According to a 2023 Deloitte report, 76% of construction firms plan to increase investment in digital tools over the next 12 months. The pressure to modernize is no longer about “staying ahead.” It’s about not falling behind.

Why? Because outdated manual workflows can no longer keep pace with the speed, scale, and complexity of today’s projects. From workforce tracking to budget control to compliance — everything demands real-time visibility and automation.

In this blog, we’ll explore why digital transformation in construction is mission-critical, what’s at stake, actionable strategies for adoption, and how platforms like OConstruction help businesses build smarter.

The Business Case: Why This Matters Now More Than Ever

The construction industry is notorious for productivity lags and paper-based processes. For decades, it lagged behind other sectors in tech adoption. But now, economic pressures, skilled labor shortages, and the increasing complexity of builds are forcing change.

Why Companies Should Care:

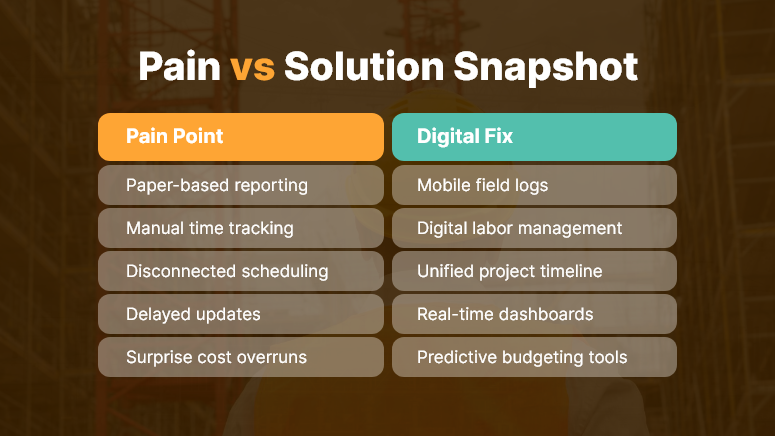

- Manual errors = cost overruns. A small miscalculation or late update on paper can cost thousands.

- Disconnected tools = miscommunication. Different teams using siloed tools create confusion and delays.

Lack of data = poor decisions. Real-time project insights lead to faster, smarter responses.

Who Benefits Most from Digital Transformation in Construction?

- Project Managers: Gain real-time visibility into cost, labor, and progress.

- Site Supervisors: Track field activity and issues from mobile devices.

- Finance Teams: Automatically sync budgets, invoices, and approvals.

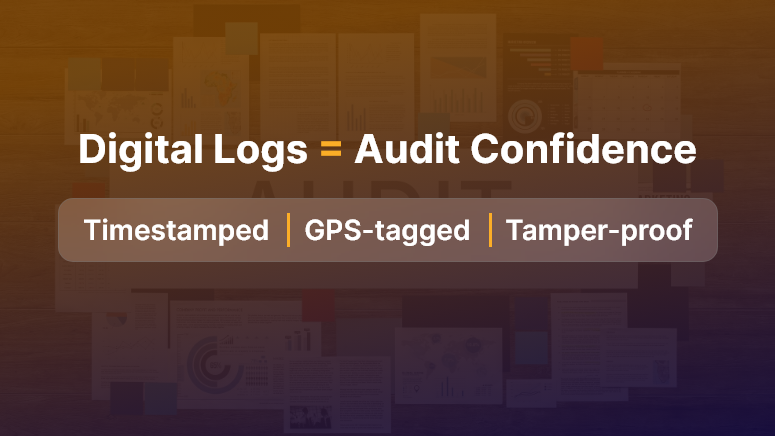

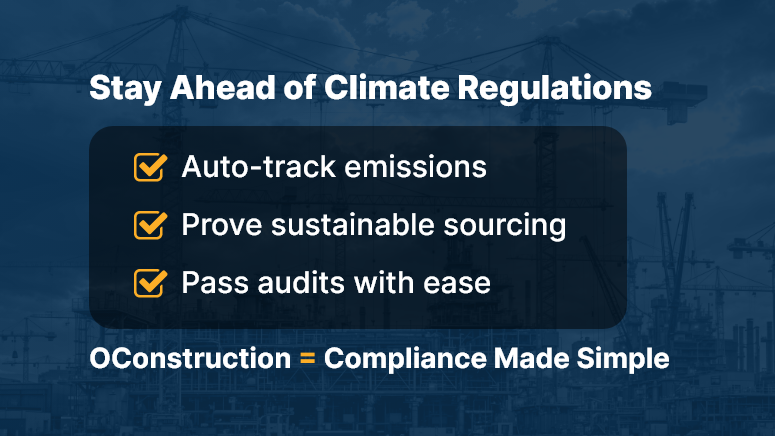

- Compliance Officers: Access up-to-date documentation instantly.

Best Practices to Drive Digital Transformation in Construction

To succeed with digital transformation, construction businesses must rethink how they plan, operate, and scale. Let’s break down best practices, quick wins, and the strategic path forward.

DO: Start with High-Impact Use Cases

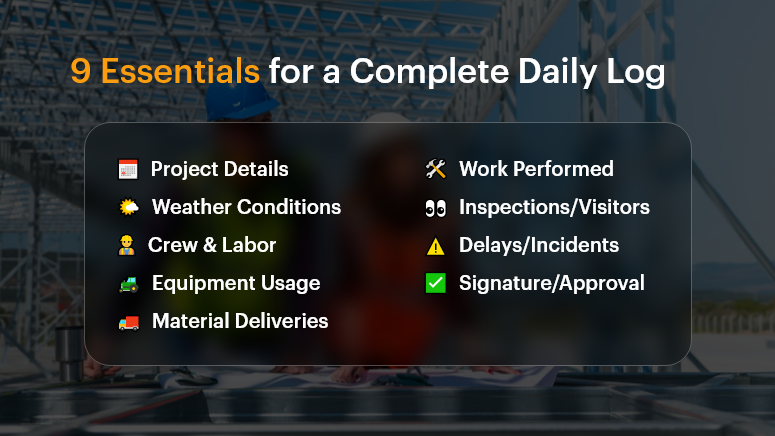

- Begin with areas like field data collection, time tracking, or project scheduling where returns are immediate.

- These modules show ROI quickly and help build internal support for broader tech adoption.

DON’T: Adopt Tools Without a Plan

- Random tool purchases create more confusion than clarity.

- Instead, align tech adoption with business goals — like reducing rework or improving jobsite safety.

DO: Choose an Integrated Platform

- Avoid juggling multiple disconnected apps.

- Use a unified digital platform like OConstruction that centralizes project scheduling, document management, budgeting, and communication.

DO: Train for Digital Readiness

- One of the biggest barriers isn’t tech — it’s people.

- Offer role-based onboarding, digital playbooks, and self-serve learning to bring crews up to speed.

DON’T: Wait for the “Perfect Time”

- There will never be a perfect moment to digitize.

- Start with a pilot project, gather results, and expand.

DO: Track and Measure Impact

- Use built-in analytics dashboards to monitor adoption, efficiency gains, and performance metrics.

- Share wins across the organization to build momentum.

Customer Use Case

For example, TeraBuild Projects, a civil infrastructure contractor, was juggling Excel sheets, whiteboards, and scattered communication apps.

By switching to OConstruction, they streamlined all project management tasks into one platform.

- Their site supervisors began logging progress from mobile devices.

- The finance team gained instant visibility into budget spend.

- Change orders and RFIs were approved 50% faster.

Within 6 months, TeraBuild reduced average project delays by 32% and cut administrative overhead by 40%.

Key Takeaways & Summary

Digital transformation in construction is not a luxury — it’s a strategic necessity. The longer you rely on manual, outdated processes, the more vulnerable you become to delays, errors, and inefficiencies.

Key insights to remember:

- Speed matters. Real-time collaboration accelerates project outcomes.

- Visibility matters. Centralized dashboards eliminate blind spots.

Integration matters. One platform to manage all your workflows is a must.

OConstruction empowers construction teams to transition from fragmented operations to smart, connected, and efficient workflows.

The bottom line?

If you want to remain competitive, digital transformation isn’t optional. It’s fundamental.