Every year, construction firms lose millions due to contract mismanagement and non-compliance. Whether it’s labor violations or poorly structured vendor agreements, the consequences are severe — penalties, project delays, and reputational damage. Legal compliance in construction contracts is no longer just about ticking boxes. With ever-evolving labor laws, environmental standards, and vendor regulations, your contracts must be airtight — and enforceable.

In this blog, we’ll explore the best practices to ensure full compliance with vendor and labor contracts, common pitfalls to avoid, and how platforms like OConstruction help streamline and secure your contract processes.

Why Legal Compliance in Contracts Matters More Than Ever

Construction is one of the most regulated industries in the world. Labor laws, safety codes, subcontractor rules, and payment terms — all must be followed to the letter. Even a small slip in contract terms or documentation can result in:

- Heavy fines and legal penalties

- Work stoppages or permit revocations

- Project delays that hurt client trust

- Damage to brand and future business opportunities

Let’s break this down with real-world relevance.

Use Case 1: Delayed Worker Payments

A mid-sized construction firm failed to adhere to the minimum wage updates in a state labor law. This caused a strike, delayed the site timeline by 4 weeks, and cost the company ₹28 lakhs in penalties and idle machinery.

Use Case 2: Incomplete Vendor Agreements

An infrastructure firm had an informal vendor agreement with a scaffolding supplier. When the vendor underdelivered and breached safety standards, the lack of proper terms made legal enforcement impossible. The firm had to bear the entire rework cost.

Ensuring legal compliance in construction contracts isn’t about fear — it’s about future-proofing your business.

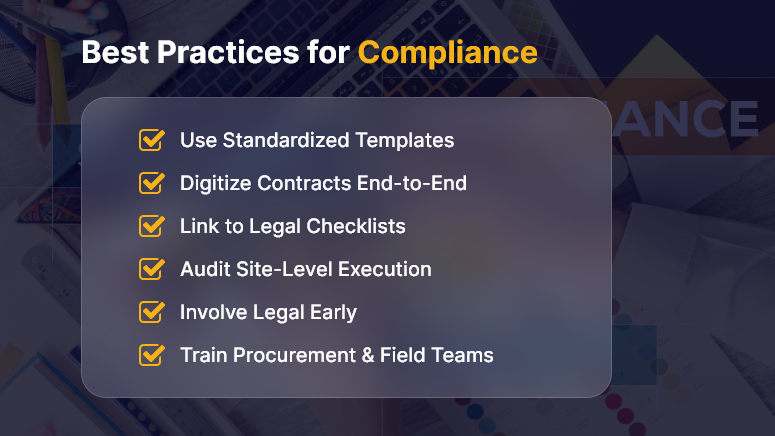

Best Practices to Ensure Contract Compliance (With Action Steps)

1. Standardize Contract Templates

Create legally vetted templates for vendors and labor contractors based on current regulations. Include essential clauses like:

- Payment milestones

- Labor rights and hours

- Insurance and liability coverage

- Dispute resolution terms

OConstruction lets you build contract templates that auto-populate key data and stay updated with regulatory changes.

2. Digitize Contract Lifecycle Management

Manual contract tracking = errors + delays.

Instead:

- Use cloud-based systems to manage drafts, approvals, versions, and renewals.

- Set automated alerts for contract renewals or compliance milestones.

- Centralize storage so stakeholders can easily access contract records.

3. Map Contracts to Compliance Checklists

Each contract should tie to a checklist of legal mandates — specific to region, scope, and contract type.

For example:

- Vendor Contracts → GST, Environmental clearance, Material specs

- Labor Contracts → Minimum wage laws, EPF/ESI registration, Working hour limits

OConstruction links every contract to dynamic checklists that flag gaps instantly.

4. Audit Frequently (And Don’t Skip the Field)

Your contract is only as good as its enforcement.

- Conduct quarterly audits of contract execution — especially at sites.

- Use mobile-friendly tools so on-ground teams can upload evidence (e.g., labor rosters, delivery slips).

- Track deviations with root cause analysis.

5. Involve Legal and Compliance Early

Too often, legal review comes last. Flip that.

- Involve legal and compliance teams during vendor onboarding and RFP reviews.

- Document every negotiation or clause revision inside the system for future reference.

- Define clear responsibilities for approvals—automated routing helps avoid bottlenecks.

With OConstruction, you can assign roles for every contract step and track approval logs.

6. Train Project and Procurement Teams

Even the best system fails if users don’t understand it.

Run training workshops on:

- Recognizing risky clauses

- Labor law changes

- Digital contract workflows

Empowered teams = fewer errors = better compliance.

Customer Example: Seamless Compliance in Action

For example, BuildEdge Infra, a multi-city contractor, struggled with labor contract tracking across its 7 sites. Using OConstruction’s contract management module:

- They standardized agreements across vendors.

- Set up real-time alerts for expiring documents.

- Enabled mobile audits to ensure on-ground compliance.

As a result, BuildEdge avoided ₹15 lakhs in non-compliance penalties in just one year, and slashed contract approval time by 40%.

Key Takeaways: Contracts Are Your First Line of Defense

Legal compliance in construction contracts is about precision, preparation, and process. If contracts are vague, manual, or delayed, they become liabilities instead of safeguards.

Remember:

- Standardization and digitization are non-negotiable.

- Proactive audits and compliance mapping reduce legal risk.

- Platforms like OConstruction make compliance easy, trackable, and scalable.

Don’t just meet the rules — master them.