Every construction team knows the frustration of juggling spreadsheets, fragmented tools, and missed deadlines. According to a recent study, 61% of construction firms face delays due to poor project communication. With so much at stake, selecting the right construction software matters more than ever.

In this post, we’ll help you cut through the noise. You’ll learn what truly matters in choosing the best software for your team, why it affects ROI, and how to evaluate tools effectively. By the end, you’ll know exactly how to pick the right system to improve efficiency and reduce errors.

Why Construction Software Selection Matters (and Who Benefits)

For contractors, project managers, field teams, and ops leaders, choosing the wrong tool can cost time, money, and morale.

Pain Points:

- Field teams lack access to real-time plans

- Delays in approvals and RFIs

- Duplicate data entry across platforms

Who Benefits Most:

- Commercial contractors managing multiple sites

- Project managers need real-time visibility

- Field engineers requiring mobile access

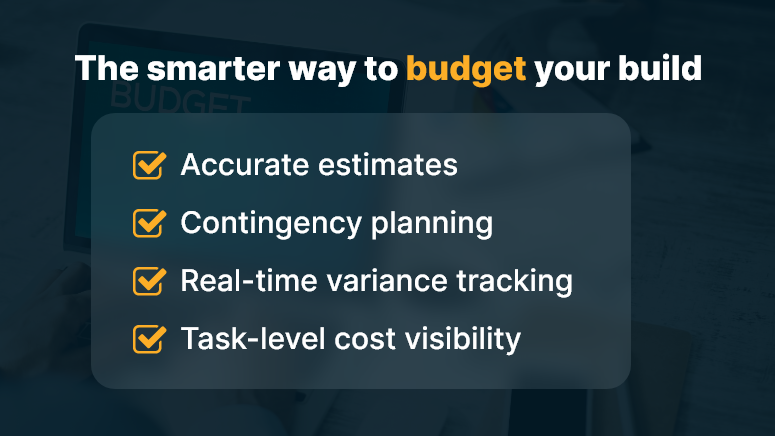

- Finance teams tracking budgets and permits

Instead of fragmented systems, the right construction software selection ensures your entire team collaborates in one platform, avoiding miscommunication and reducing rework.

Imagine less time chasing signatures and more time getting projects delivered on time and on budget.

Best Practices & Actionable Steps to Select Construction Software

What to Do

- Define Business Needs First

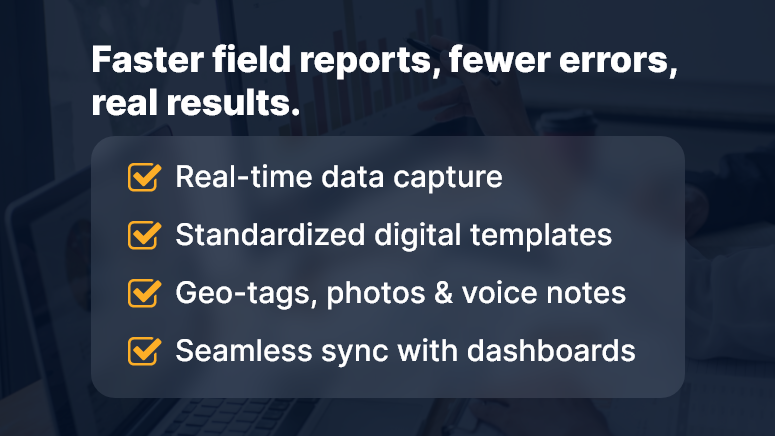

Clarify what your team needs: mobile access, document control, budgeting, or scheduling. Avoid choosing a tool without a clear problem to solve. - Prioritize Usability & Mobile Access

Field users should be able to upload photos, manage RFIs, and view plans via phones or tablets. If the interface frustrates them, adoption drops fast. - Ensure Seamless Integrations

Your ideal software should sync with accounting systems, BIM tools, or ERP platforms. Good construction management software reduces manual entry and errors. - Look for Role-Based Permissions

Project managers, subcontractors, and office staff need different levels of access. Choose software that supports granular permissions and audit trails.

What to Avoid

- Selecting software based on feature count alone

- Ignoring customer support and training options

- Underestimating onboarding time and training needs

Quick Wins

- Trial with a single active project — see how the team adopts and thrives

- Use built-in mobile apps from day one, not later

- Set KPIs like approval turnaround time or rework reduction to measure success

Evaluation Framework

- Identify Core Use Cases: e.g., site access, RFI management, subcontractor coordination

- Request Demos with Real Scenarios

- Pilot with Key Team Members

- Get Feedback & Score Usability

- Assess ROI: reduced delays, fewer errors, faster approvals

Customer Use Case: Software Selection in Action

For example, Skyline Contractors, a mid-sized commercial builder, evaluated multiple platforms before choosing a system that offered real-time mobile plan access, automated RFI workflows, and integrated budget tracking.

- They cut RFI turnaround by 45%

- Reduced document retrieval time from hours to minutes

- Improved subcontractor compliance submissions by 30%

Here’s how: They piloted the software on two live sites and gathered user feedback regularly. That approach ensured successful adoption across field and office teams.

Key Takeaways & Closing Summary

Choosing the right construction software isn’t just about features — it’s about solving real problems for your field, office, and finance teams.

- Focus on your team’s pain points first, then evaluate tools

- Prioritize mobile usability, tight integrations, and role-based permissions

- Pilot with real projects, measure success, and scale gradually

By taking a structured and team-aligned approach, your construction software selection becomes a transformational step — not just an IT purchase.