Did you know that up to 35% of construction projects exceed their initial budget due to poor material cost tracking and mismanagement? According to a McKinsey study, construction productivity has shown minimal improvement over the past two decades, largely due to companies’ struggles with cost control and inefficiencies.

For most contractors, materials account for 50–70% of total project costs. If you’re not monitoring these expenses in real-time, your margin is at risk. From fluctuating raw material prices to delayed deliveries and vendor disputes, the challenges keep piling up.

This blog will teach you how to track material costs without losing your margin. We’ll cover why this matters in today’s construction business, best practices and frameworks you can apply, and how an integrated platform like OConstruction makes the process smarter, faster, and more profitable.

Business Relevance & Why It Matters

Margins in construction are notoriously thin. A small slip — say a 5% rise in cement cost or unaccounted wastage on-site — can reduce profits drastically. Businesses that fail to track material costs accurately often face:

- Cost Overruns: Materials purchased at inflated prices or in excess quantities.

- Project Delays: Missing deliveries disrupt schedules and increase labor idle time.

- Client Disputes: Billing mismatches between estimates and actual expenses.

- Compliance Risks: Lack of documentation during audits or inspections.

Who Benefits the Most from Cost Tracking?

- Residential Builders: They need to balance affordability for clients while keeping margins intact.

- Infrastructure Contractors: Large-scale projects involve massive procurement cycles; even small errors scale up to millions.

- Commercial Developers: With tight timelines, they require precise vendor coordination to avoid penalties.

Pain vs. Solution Contrast

Pain: Many firms rely on paper-based logs, spreadsheets, or disconnected systems. Reconciling purchase orders, invoices, and deliveries consumes hours — yet errors slip through.

Solution: An integrated platform like OConstruction centralizes everything. From procurement to delivery verification and expense tracking, every transaction is logged digitally. Managers gain real-time visibility, finance teams get accurate data, and site engineers spend less time on paperwork.

Bottom line: Tracking material costs is not just accounting; it’s a strategic move to safeguard margins and scale your business profitably.

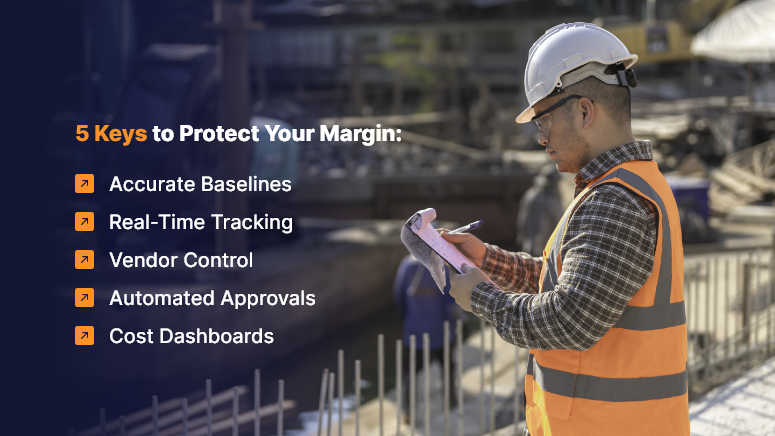

Best Practices, Frameworks, and Actionable Strategies

1. Build a Transparent Cost Baseline

Every successful project begins with an accurate baseline. This includes expected material quantities, negotiated vendor rates, and projected delivery timelines.

- Do: Use digital tools to create baselines that auto-link with budgets and schedules. In OConstruction, baseline costs sync with project tasks for full alignment.

- Don’t: Depend solely on historical averages — market rates for steel, cement, and aggregates can change weekly.

Pro Tip: Add contingency buffers (5–10%) for volatile materials. This gives you breathing space without eating into margins later.

2. Track in Real-Time, Not After the Fact

Traditional month-end reconciliations are too late. By the time discrepancies surface, the damage is done. Real-time cost tracking changes the game.

- Quick Win: Record material receipts instantly. With OConstruction, site staff can log deliveries using GPS-tagged photos and timestamps.

- Best Practice: Configure alerts when actual costs cross 90% of budgeted levels. This proactive monitoring helps prevent overruns.

Example: If a steel consignment arrives short, the system flags it immediately, allowing procurement teams to raise disputes before payment.

3. Centralize Vendor and Contractor Data

When vendor invoices, purchase orders, and delivery challans are scattered across emails, files, and spreadsheets, reconciliation is painful.

- Do: Centralize procurement workflows in one system. OConstruction links vendor contracts, SLAs, and invoices in a single hub.

- Don’t: Approve payments without cross-checking against verified delivery logs.

Result: This reduces duplicate payments and strengthens vendor accountability.

4. Prevent Material Wastage

On average, 10–15% of materials go to waste due to poor storage, over-ordering, or theft. Wastage is a silent margin killer.

- Step 1: Track issued vs. consumed material in real-time.

- Step 2: Identify high-wastage categories with analytics.

- Step 3: Introduce recycling, resale, or redistribution processes for surplus materials.

With OConstruction, companies generate waste reports at both project and company levels, giving leaders data-driven insights to plug leaks.

5. Standardize Approval Workflows

Unauthorized purchases often derail budgets. A robust approval workflow prevents unnecessary costs.

- Quick Win: Automate approval triggers — e.g., any purchase order above ₹50,000 requires finance approval.

- Best Practice: Assign role-based permissions so site engineers raise requests, but final approval sits with procurement managers.

Impact: Transparency, accountability, and zero “off-the-books” spending.

6. Use Dashboards for Visibility

Dashboards transform raw data into actionable intelligence.

- Do: Customize dashboards to track top categories like steel, cement, aggregates, and electricals.

- Don’t: Overload managers with vanity metrics — focus on KPIs tied to margin protection.

With OConstruction, executives get a bird’s-eye view of all projects while project managers see granular, on-site material costs.

7. Integrate Material Tracking with Project Schedules

Disconnected procurement and scheduling is a recipe for chaos. If materials don’t arrive on time, project tasks stall, increasing labor costs.

- Do: Link delivery timelines directly with Gantt charts and milestones.

- Best Practice: Tie vendor SLAs with project tasks. For instance, steel delivery is synced with slab casting schedules.

Benefit: Timely delivery, fewer delays, and reduced idle costs

8. Leverage Predictive Analytics

Don’t just track material costs — predict them. Predictive analytics helps you forecast risks before they occur.

- Example: If cement prices rise seasonally in Q3, the system can flag early purchase recommendations.

- With OConstruction: AI-powered insights help managers make proactive decisions, safeguarding both budgets and timelines.

Customer Story/Use Case Example

For example, BuildSmart Contractors, a mid-sized infrastructure company, faced recurring cost overruns. On average, projects exceeded budgets by 12% due to duplicate purchases, vendor disputes, and undocumented wastage.

After adopting OConstruction’s real-time cost tracking:

- All material receipts were logged with photo + GPS verification.

- Vendor payments required automated approvals tied to verified delivery notes.

- Dashboards provided weekly variance reports for management review.

Result? Within six months, BuildSmart reduced overruns to just 3%, saving over ₹1.2 crore (~$150,000) and increasing client satisfaction scores by 30%.

Key Takeaways & Closing Summary

Controlling material costs is not optional — it’s essential for survival in today’s construction business. Companies that fail to adopt digital tools face shrinking margins, delays, and client dissatisfaction.

Key Takeaways:

- Set a clear baseline with updated vendor rates and realistic contingencies.

- Track in real-time to detect and fix cost issues instantly.

- Centralize procurement for accountability and transparency.

- Cut wastage by monitoring issued vs. consumed materials.

- Automate approvals to stop uncontrolled spending.

- Use dashboards and predictive analytics for faster, smarter decisions.

In summary, firms that track material costs digitally not only avoid overruns but also strengthen trust with clients, vendors, and stakeholders.

Margins are tight, competition is fierce, and regulations are strict. The companies that thrive are those that digitize. With OConstruction, you gain the tools to track material costs, protect your margins, and future-proof your projects.

FAQs on Tracking Material Costs

1. Why is tracking material costs so important in construction projects?

Tracking material costs is critical because materials make up 50–70% of a project’s budget. Even small errors — like a 5% increase in steel prices or unrecorded wastage — can erode profit margins. Real-time tracking ensures transparency, prevents overruns, and helps contractors make data-driven decisions to protect profitability.

2. What are the common challenges in tracking material costs?

The biggest challenges include fluctuating raw material prices, manual errors in spreadsheets, lack of vendor accountability, poor record-keeping, and delayed reconciliations. Many companies still depend on outdated methods, leading to discrepancies, wastage, and budget overruns.

3. How can digital tools like OConstruction help reduce material cost overruns?

Platforms like OConstruction centralize procurement, inventory, and cost data. Features like real-time delivery logging, GPS/photo verification, automated approvals, and dashboards give managers full visibility. This helps detect discrepancies early, avoid duplicate payments, and align purchases with project schedules — reducing overruns significantly.

4. What’s the difference between cost estimation and cost tracking?

- Cost Estimation: Forecasting project expenses based on material requirements, labor, and vendor rates.

- Cost Tracking: Monitoring actual material purchases, deliveries, and consumption against the estimate in real-time.

Both work together — accurate estimation sets the baseline, while tracking ensures the project stays within budget.

5. How can construction companies prevent material wastage?

Companies can prevent wastage by:

- Tracking issued vs. consumed materials digitally.

- Storing materials properly to avoid damage.

- Using waste analytics to identify problem categories.

- Recycling or redistributing surplus materials.

With OConstruction, managers generate waste reports at the project and company levels to pinpoint leakages.

6. What KPIs should be monitored when tracking material costs?

Key performance indicators (KPIs) include:

- Budget vs. actual material costs.

- Wastage percentage by category.

- Vendor delivery compliance rate.

- Variance in material usage across projects.

- Percentage of unauthorized or unapproved purchases.

These metrics help evaluate efficiency and control margins.

7. Can small and mid-sized construction firms also benefit from cost tracking software?

Absolutely. In fact, smaller firms are often hit harder by cost overruns since their margins are thinner. Digital tools give SMB contractors the same visibility and control as large enterprises, making them more competitive without adding complex overhead.

8. How does real-time tracking differ from monthly reconciliations?

Monthly reconciliations catch problems after the damage is already done. Real-time tracking, on the other hand, identifies discrepancies immediately. For example, if a cement delivery is short by 10 bags, the system flags it instantly — preventing unnecessary payments and project delays.

9. How can predictive analytics improve material cost management?

Predictive analytics uses historical data and market trends to forecast cost risks. For example, if steel prices typically rise in the rainy season, the system can recommend early procurement. OConstruction’s AI-driven insights help companies stay proactive, not reactive, when managing costs.

10. What’s the ROI of implementing a digital material cost tracking system?

The ROI comes from reduced overruns, less wastage, faster approvals, and stronger vendor accountability. Case studies show companies cutting overruns by 8–12% within months of adopting digital cost tracking — often saving lakhs or even crores depending on project size. In short, the software pays for itself quickly while safeguarding long-term margins.