Construction sites are among the most hazardous workplaces — accounting for one in five worker deaths annually, according to OSHA. But many of these accidents are preventable with a structured site safety checklist.

A safety checklist isn’t just a compliance form — it’s a real-time tool to save lives, reduce liability, and build safer, more productive job sites. From personal protective equipment (PPE) to emergency procedures, every checklist item matters.

In this blog, we’ll walk you through 10 essential checklist components, why they matter, and how a digital platform like OConstruction simplifies it all.

Why a Site Safety Checklist Is a Must-Have for Every Project

Let’s face it — site safety is more than a legal requirement; it’s a business advantage.

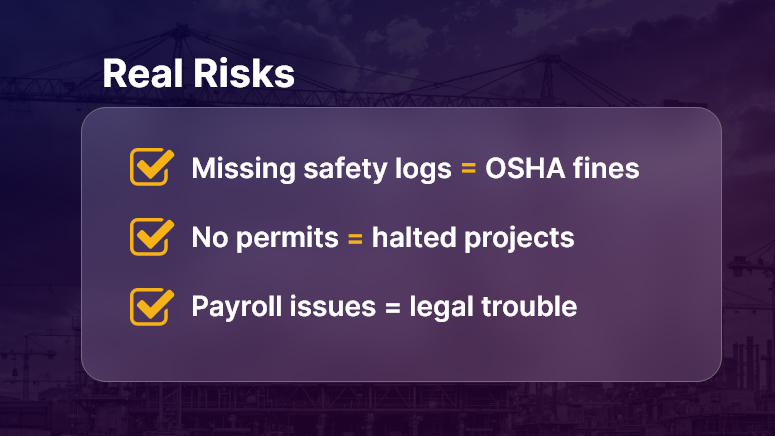

Delays caused by safety violations, lawsuits, and workforce injuries can tank project budgets and timelines. The right safety practices not only prevent loss but also build trust across stakeholders.

Real-World Impacts:

- General contractors can avoid costly rework by identifying hazards early through routine safety checks.

- Project managers benefit from real-time visibility into site safety data, reducing incident response time.

- EHS managers can ensure compliance with OSHA standards while reinforcing a culture of safety.

Without a standardized site safety checklist, important tasks fall through the cracks — and your team is left exposed.

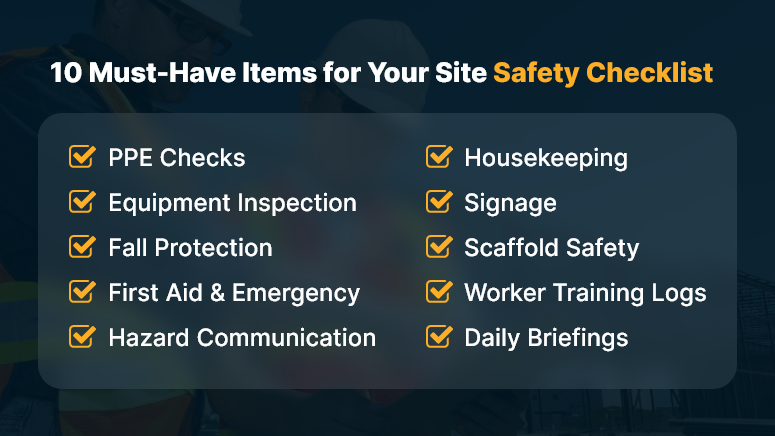

10 Site Safety Checklist Must-Haves (And How to Get Them Right)

Let’s break down the 10 critical components every construction site must cover:

1. PPE (Personal Protective Equipment) Checks

Make sure helmets, gloves, boots, eyewear, and high-vis clothing are available and worn correctly. Inspect for wear-and-tear or expired certifications.

2. Tool and Equipment Inspection

Check that all equipment is operational and tagged for safety. Malfunctioning gear is a top cause of on-site injuries.

3. Fall Protection Systems

Verify the installation and use of guardrails, harnesses, and fall arrest systems—especially for projects above six feet.

4. First Aid & Emergency Supplies

Ensure kits are fully stocked, accessible, and marked. Emergency eye wash stations and fire extinguishers should be part of every site.

5. Hazard Communication

All chemicals and materials must be labeled and have associated SDS (Safety Data Sheets) available to workers.

6. Housekeeping Standards

Clutter, debris, and spills increase risks. Confirm regular cleaning protocols are followed and materials are properly stored.

7. Signage and Barricades

Install visible warning signs in hazardous zones. Temporary barricades should be used to isolate high-risk areas.

8. Scaffold and Ladder Safety

Inspect scaffolds for structural integrity and confirm ladders meet load-bearing and positioning requirements.

9. Worker Training Logs

Track that each worker has completed necessary training: fall protection, lockout/tagout, PPE use, and emergency response.

10. Daily Safety Briefings

Hold toolbox talks at the start of each shift. Document attendance and topics discussed for compliance tracking.

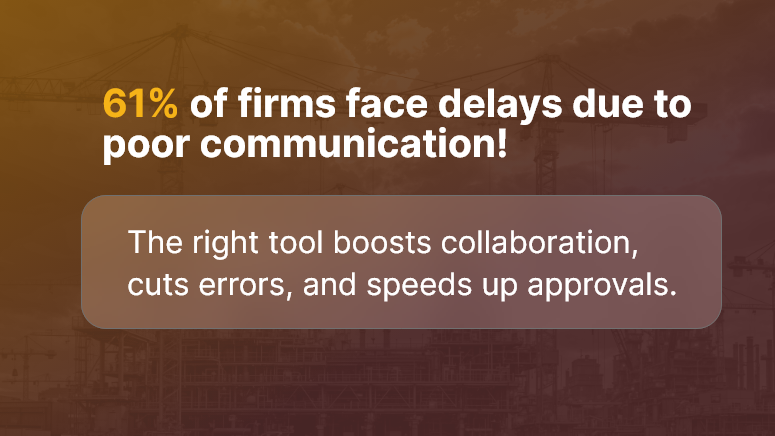

Pro Tip: Use OConstruction’s digital checklists to auto-remind supervisors of daily inspections, document outcomes, and trigger alerts for missing items.

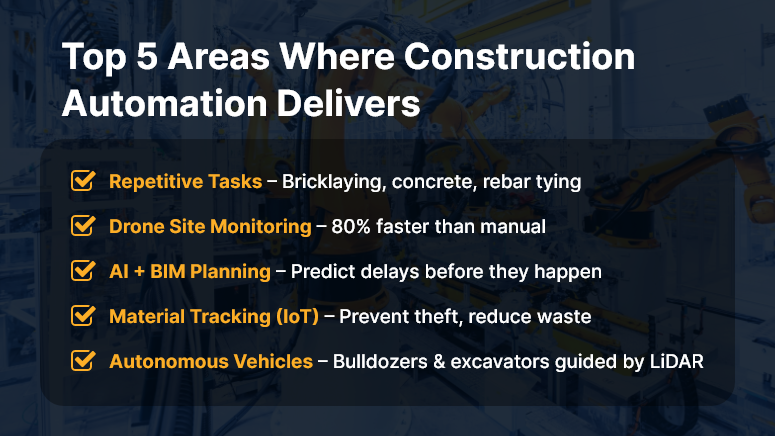

How One Contractor Cut Incident Rates by 45%

BrixCore Projects, a mid-sized contractor in Mumbai, used OConstruction’s safety checklist feature to reduce job-site injuries by 45% in just six months.

Here’s how: They digitized all safety protocols, set auto-reminders for daily inspections, and integrated QR codes for on-site hazard reporting. Field staff could instantly flag safety issues, and managers could act immediately — no paperwork delays.

This resulted in fewer compliance lapses, faster responses to risks, and greater worker confidence on-site.

Key Takeaways: Don’t Just Build Fast — Build Safe

Safety isn’t just a policy—it’s a practice. When it’s built into daily routines, it becomes second nature.

- A site safety checklist creates structure and accountability on every job site.

- It reduces risks, ensures compliance, and enhances team confidence.

- Digital platforms like OConstruction eliminate paperwork delays and ensure real-time visibility into safety tasks.

Want fewer incidents, better compliance, and faster inspections? Start with a checklist that’s smart, mobile, and built-in.